The University of Pretoria is well advanced in a programme to experimentally validate numerical simulation software developed by the Council for Scientific and Industrial Research (CSIR) to accurately model the sloshing of fuel in an aircraft’s fuel tank. This was unveiled at a recent joint briefing at the university.

The project is taking place under the aegis of the Aerospace Industry Support Initiative of the Department of Trade and Industry. It involves Business Enterprises at the University of Pretoria (BEatUP), the CSIR and local aerospace company Denel Aerostructures (DAe).

The project’s origins lie in 2013, when the CSIR demonstrated software to simulate complex fluid motions to DAe. “DAe was very impressed with the potential of the software to predict fuel loading in aircraft fuel tanks,” noted retiring DAe designer Andries Visser. “The thing with software is [that] we need to validate what the software predicts in real life.”

“BEatUP was contracted by the CSIR,” reported BEatUP project and test engineer Jan Eksteen. “A laboratory was set up to simulate sloshing [in real life].”

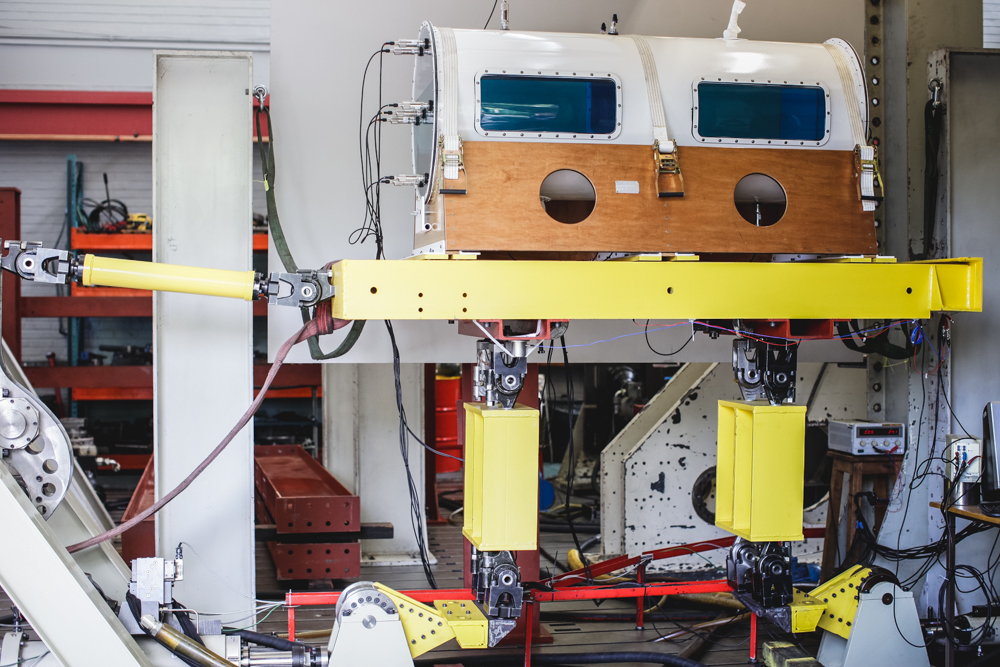

“It was decided to fabricate two test tanks,” said Visser. “DAe’s job was firstly to design these tanks.” The first tank is cylindrical and is called the validation tank, which is 1 616 mm long and 635 mm in diameter. It is based on an external ferry tank for the Denel Rooivalk attack helicopter. This was used because Denel has the design authority for that tank. The second tank is rectangular in profile, with a length of 1 600 mm, a width of 600 mm and a height of 450 mm. Called the application tank, it is based on the fuel tank for an unmanned aerial vehicle.

The two tanks are mounted on test rigs. The test rig for the validation tank was specifically developed for the test programme. It can subject the tank to pitch rotation, longtitudinal motion (‘translation’, in engineering jargon) and vertical motion, and can do all of these actions simultaneously, if required. The tank was instrumented with three very sensitive seismic accelerometers and 14 high-precision pressure sensors, of laboratory quality and with a range of one bar each. It has an 18-channel data logging capability. The tests are performed and the outputs are measured. The data is then processed to get the required results.

The tests are done with three different water levels in the tank: low, half-full and high. They are also done at three frequencies and at others chosen at random. The first series of tests is being done without a baffle in the tank (a baffle reduces sloshing); these are now about 70% complete. They will be followed by a second series of tests, identical to the first, except that the tank will be fitted with a baffle. “This is not a research project,” highlighted CSIR aeronautical researcher Johan Heyns. “It’s so that we can improve industry.”

The CSIR used a number of open-source software libraries to develop its numerical simulation system. “We don’t want to reinvent the wheel,” he affirmed. “There’s a lot of software that has been developed. We wanted to use that.” The focus of the CSIR was on improving accuracy and increasing flexibility.

“It’s one thing to have nice [numerical] simulations. It’s another to have accurate results,” he pointed out. But the results of the validation process have been very encouraging. “There’s a very good correlation between the numerical [simulation] and experimental results. They’re almost too good! This is really encouraging.”

The numerical simulation is very accurate in its predictions of slosh wave frequency and amplitude. While it is less accurate with regard to pressure, it is far more accurate than any alternative system. “This tool allows us to provide engineers, within a week or two, with something that will improve their designs,” stressed Heyns. “This is a capability that will really enable South African industry. We can design safe systems [with this system]. “We don’t have to overdesign them. It really provides South African industry with a cost- effective solution.”